Elektrische Membranpumpe (PVDF) erfüllt hohe Anforderungen

Unsere elektrische Membranpumpe aus Polyvinylidenfluorid (PVDF) überzeugt im Vergleich mit PTFE durch eine verbesserte Druckfestigkeit und Steifigkeit. Bei Polyvinylidenfluorid handelt es sich um hochkristallinen, thermoplastischen Kunststoff, der über ausgewogene mechanische Eigenschaften verfügt. Zudem gilt dieser Kunststoff als physiologisch unbedenklich und ist besonders beständig gegenüber energiereicher Strahlung. Zu beachten ist jedoch, dass die elektrischen und dielektrischen Eigenschaften von PVDF aufgrund der Molekularstruktur eingeschränkt sind.

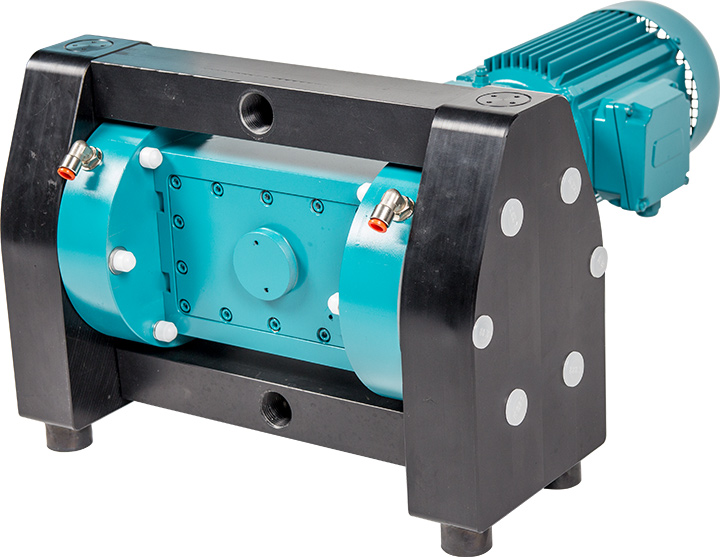

Elektrische Membranpumpe mit PVDF-Kunststoffgehäuse

Unsere PVDF-Membranpumpe benötigt weder Hydraulikflüssigkeit noch permanente Luftzufuhr, da sie mithilfe eines Elektromotors angetrieben wird. Mit dieser energieeffizienten Arbeitsweise eignet sich die Doppelmembranpumpe vor allem für Systeme, die auf einen niedrigen Maximaldruck (6 bar) angewiesen sind. Zudem erfüllt unsere Kunststoffpumpe höchste Hygieneanforderungen und wird häufig in der Lebensmittel- oder Chemieindustrie eingesetzt. Neben einer elektrischen Membranpumpe mit PVDF-Gehäuse erhalten Sie bei Dellmeco auch elektrische oder selbstansaugende Membranpumpen aus anderen Kunststoffen wie zum Beispiel Polytetrafluorethylen (PTFE) oder Polyethylen (PE).

Optionales Zubehör und Sondervarianten ebenfalls erhältlich

Wir führen nicht nur elektrische Doppelmembranpumpen mit verschiedenen Kunststoffgehäusen, sondern bieten auch unterschiedliche Sonderausführungen und Zusatzoptionen an. Bei Bedarf erhalten Sie in unserem Sortiment unter anderem Hubzähler in diversen Ausführungen. Damit können Sie der Pumpe die Zahl der Hübe vorgeben. Ist die eingestellte Hubanzahl erreicht, wird die Pumpe mittels ebenfalls optional verfügbarem Magnetventil abgeschaltet. Ein Rückspülsystem zur Restentleerung der Leitungen sowie ein Sperrkammersystem runden die möglichen Sondervarianten ab. Zusätzlich finden Sie in unserem umfangreichen Portfolio sowohl für die elektrische Membranpumpe als auch für selbstansaugende Pumpen nützliches Zubehör. Dazu zählt unter anderem ein Feuchtigkeitssensor zur Membranbruchüberwachung. Wenn der Sensor Alarm meldet, kann das Alarmsignal an ein ebenfalls optional verfügbares Magnetventil weitergeleitet werden. Dadurch wird die Luftzufuhr unterbrochen und die Pumpe stoppt.

Sie haben Fragen zu der elektrischen Membranpumpe aus PVDF-Kunststoff? Mit unserem spezifischen Know-how stehen wir Ihnen gerne beratend zur Seite und unterstützen Sie bei der Auswahl mit einer individuellen und anwendungsbezogenen Beratung. Nehmen Sie Kontakt zu uns auf!