Eine elektrische Doppelmembranpumpe aus Polytetrafluorethylen (PTFE) ist aufgrund ihrer besonderen chemischen Eigenschaften für den Einsatz in verschiedensten Branchen geeignet. Der Kunststoff Polytetrafluorethylen ist ein vollfluoriertes Polymer mit glatter Oberfläche, die eine schonende Materialförderung begünstigt. In Reinform ist PTFE zwar nur bedingt in abrasiven Medien einsetzbar, da schnell Kaltfluss entsteht. Der große Vorteil besteht jedoch darin, dass PTFE physiologisch unbedenklich, diffusionsundurchlässig und gegen nahezu alle Chemikalien beständig ist.

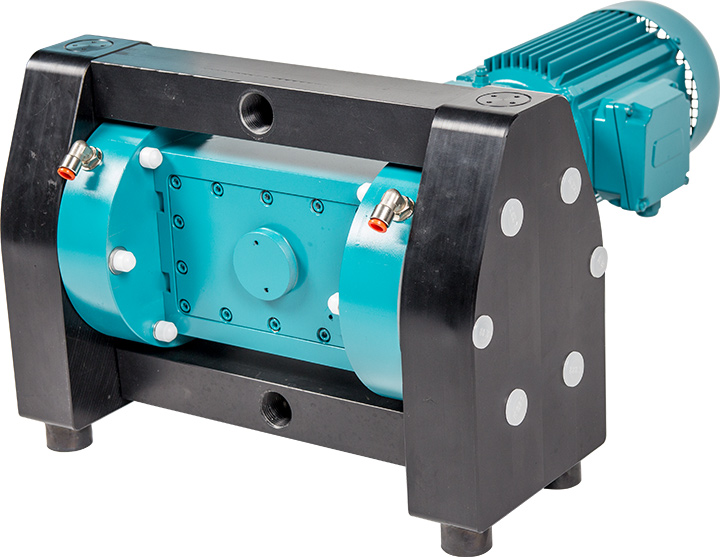

Elektrische Doppelmembranpumpe mit PTFE-Kunststoffgehäuse

Im Gegensatz zu pneumatischen Pumpen, die mit Druckluft arbeiten, werden die elektromechanischen Membranpumpen mittels Elektromotor angetrieben und benötigen weder eine permanente Luftzufuhr noch Hydraulikflüssigkeit. Dieses Funktionsprinzip sorgt für eine energieeffiziente Arbeitsweise und eignet sich insbesondere für Systeme, die nur einen niedrigen Maximaldruck von 6 bar benötigen. Wir führen bei Dellmeco nicht nur elektrische Doppelmembranpumpen mit PTFE-Gehäuse, sondern auch elektrische oder pneumatische Membranpumpen aus anderen Kunststoffen wie zum Beispiel Polypropylen (PP) oder Polyethylen (PE).

Sondervarianten & Zubehör für die elektrische Doppelmembranpumpe

Unsere elektrische Doppelmembranpumpe gibt es nicht nur mit unterschiedlichen Kunststoffgehäusen, sondern auch in verschiedenen Zusatzoptionen und Ausführungen. Optional erhalten Sie bei Dellmeco eine leitfähige Version der Pumpe, die für alle gängigen ATEX-Zonen, inklusive Zone 1 (II 2/2G Ex h IIC T3…T4 Gb), gilt. Dabei bleiben die technischen Eigenschaften erhalten, sodass die Pumpe problemlos bei erhöhter Brand- und Explosionsgefahr verwendet werden kann. Wenn Sie sich für die Hochdruckvariante entscheiden, eignet sich die Kunststoffpumpe unter anderem für die Beschickung von Kammerfilterpressen oder Sprühdüsen. Weiterhin ist ein Rückspülsystem für die Restentleerung der Leitungen als Zusatzoption erhältlich. Unsere vielfältige Produktauswahl umfasst darüber hinaus praktisches Zubehör sowohl für die elektrische Doppelmembranpumpe als auch für selbstansaugende Pumpen. Bei uns erhalten Sie unter anderem einen Pulsationsdämpfer, der für einen gleichförmigen Förderstrom sorgt sowie einen Feuchtigkeitssensor zur Membranbruchüberwachung.

Sie interessieren sich für unsere elektrische Doppelmembranpumpe aus PTFE-Kunststoff oder haben Fragen zu anderen Pumpen von Dellmeco? Unsere qualifizierten Mitarbeiter stehen Ihnen gerne als kompetenter Ansprechpartner zur Verfügung und bieten Ihnen eine anwendungsbezogene Beratung für Ihren individuellen Fall. Kontaktieren Sie uns!